The MEP installations can face many mistakes during the construction of the projects. This is in case the work is done by technicians who are not well-experienced or careless.

So, in this article, I tried to focus on the common mistakes made by some electrical designers and execution teams while installing the MEP services in the projects.

List of MEP Common Mistakes

Mistake number One

The electrical team will exceed the permitted maximum filling ratio of a conduit or a tray, which means more wires or cables are pulled inside a conduit that exceeds the accepted fill ratio.

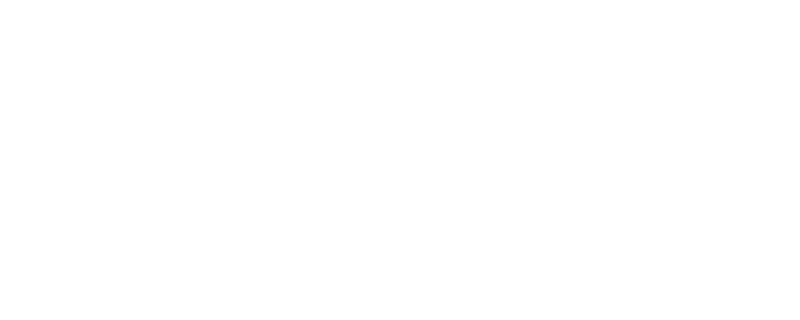

As per NEC table 1 in photo no.1, the maximum allowable fill ratio for more than 2 cables inside a conduit is 40%, but sometimes the designer or the installer or both of them forget or don’t take care of this point, so that the construction team will have a lot of wires or cables are pulled inside a conduit and take space inside the conduit more than the allowable fill ratio.

Mistake Number Two

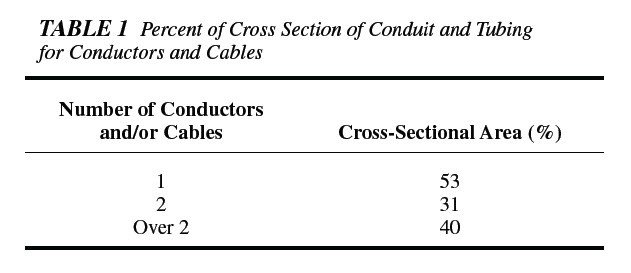

The electrical forgot to install Junction boxes in the routing of electrical exposed EMT conduits, although we have more than four 90-degree bends because this affects on cable or wire-pulling inside the conduit.

Also, later for any maintenance purpose, pulling new wires/cables or re-pulling them will be very difficult. Please refer to photo no. 2, a screenshot from NEC article number 358.26, which talks about the same matter.

Mistake number Three

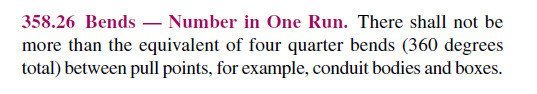

This mistake happens when the electrical team does not install an expansion coupler where the electrical conduit crosses a structural expansion joint.

Is either this conduit embedded in the concrete slab before its casting, or the conduit is installed exposed in the slab soffit.

Please refer to photo no. 3 &4 show the expansion couplers from manufacturers’ catalogs for LSF conduit, which will be embedded in the concrete, and also EMT conduit, which will be installed as exposed in the slab soffit, respectively.

Mistake number Four

In this mistake, we will talk about not installing inspection bends at the routing of an exposed when it’s crossing a dropped concrete beam.

Usually, we can see this mistake happens especially at the basement level because may we will have a lot of concrete drop beams in the basement level.

At the same time, if the electrical didn’t install the conduits of the different electrical/Low current systems (like BMS conduits, Electrical lighting & Power conduits, Data Conduits, Fire Alarm conduits…etc.) embedded in the concrete slab of the basement before its casting, so you will have many conduits shall be installed exposed, and in this case, there’s a high chance that these conduits may cross the concrete drop beams.

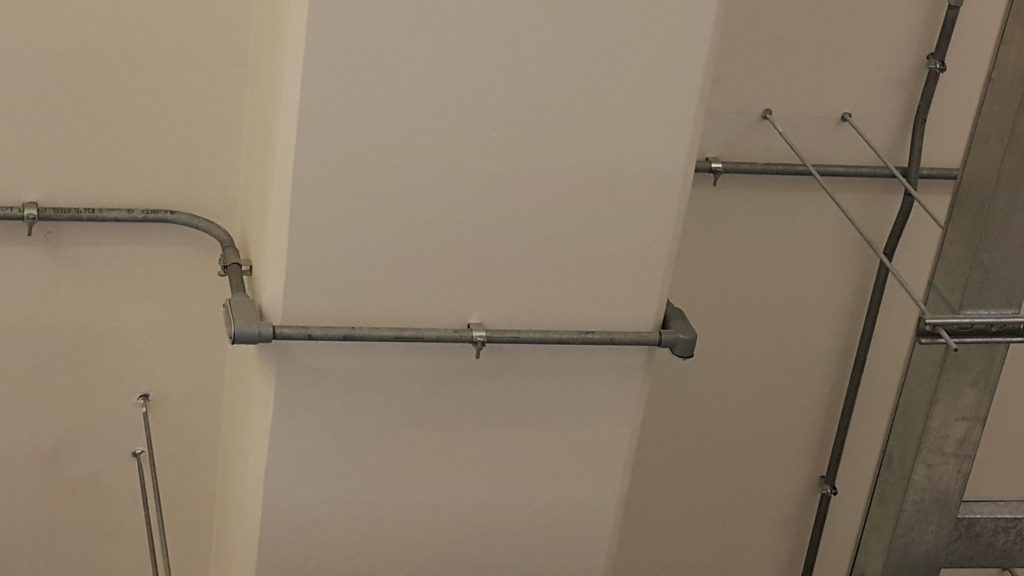

As you can in the following photo, which I captured from one of our projects, you can notice when the RGS exposed conduits try to cross the drop concrete beam, it needs 4 bends (90 degrees), which will be very difficult to pull the wires/cables later.

That’s why we shall install inspection bends before and after the concrete drop beams. This is to make the wire-pulling process easy as possible.

Moreover, without installing these inspection bends, it will be difficult to pull or do maintenance for the wires or cables which are installed inside the conduit.

In this photo, we have two inspection bends, one before the drop concrete beam and the other one after the concrete beam. We installed a saddle between them to hold the RGS pipe with the beam.

Mistake number Five

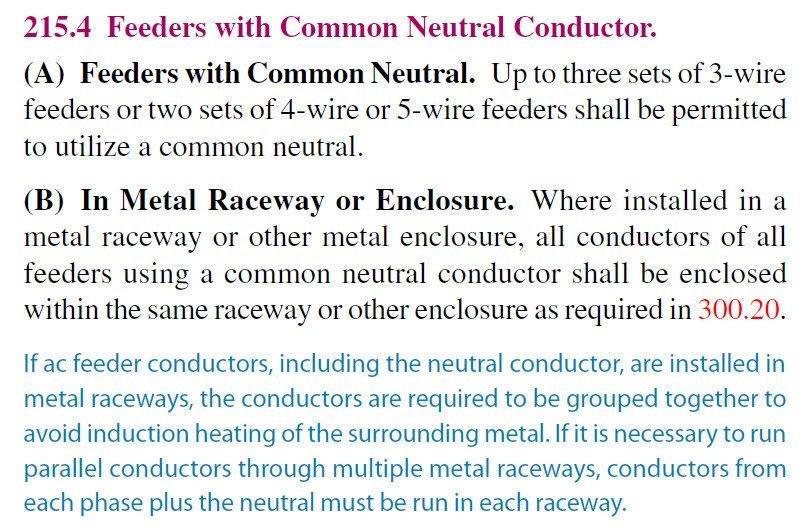

This mistake can be made by newbie electricians, who they will pull a single wire that carries a voltage inside a metal conduit, which will cause induction currents and, in the end, will cause the burning of the wire. Please refer to photo no. 6 from NEC article no. 215.4, which describes the same.

Mistake number Six

This mistake is a common mistake in construction projects. It can happen while installing the electrical conduit (uPVC or PVC) in the concrete slab before casting.

Due to no proper coordination between electrical and mechanical teams, this coordination must be done first in the shop drawing stage before the construction, but lack of proper coordination can cause the electrical conduits may cross in the place of a mechanical penetration.

Mostly, this will happen when the mechanical penetration is not yet marked on the plywood of formwork, so the delay in marking the mechanical openings/penetrations on the slab by the mechanical team, the more chance to cut these electrical conduits which are passing at the same location of these penetrations and are not rerouted.

Also, the same problem can happen with the electrical team themselves. This is when the electrical team doesn’t mark first the locations of their required openings for electrical cable trays, ICT cable trays, Busways…etc.

So, the delay in marking these electrical/ICT openings, the more chance of having a clash between the electrical conduits on the slab with these electrical/ICT openings.

In all cases, the best solution for this mistake is to mark and directly provide block-outs using plywood wooden boxes or (Sleeves) of all the mechanical & electrical penetrations in the slab. This is before starting the installation of the electrical conduits.

This is shown in photo no. 7

Mistake number Seven

This is a silly mistake. It happens due to confusion on the electrician’s side between the stud anchor bolt & unifix.

The confusion will come from the proper drill pit size which will be used for drilling the hole of the stud anchor bolt because, in most cases, the electrician is used to install the unifix, so when he has a unfix with a size 16mm (M16), he will need to use a concrete drill pit with a size 18mm (extra 2mm than the size of the unifix).

But, when he needs to install a Stud Anchor Bolt with a size 16mm (M16), in this case, he needs to use a drill bit with a size 16mm.

Thank you for your time in reading this article. See you later with other explanations in the MEP division.

Expert Advice:

Enroll now in this and get immediate access to more than 170 lectures in our different online courses. Plus, during your subscription, you will get access to all the new future courses & lectures added to the package.

You can get your 24 Hours trial today for just $3 and get access to all courses. You can cancel your subscription at any time.

Note: We offer you 14-Day Money Back Guarantee if you don’t like the course

If you would like to read more about the different MEP topics, here’s a list of our recent MEP articles:

1- Your Easy BMS Guide “Building Management System” in Projects

2- Internet of things ( IoT ) the new age of technology

3- Fire Alarm System as You need to Know

4- The Most Important 10 PPE in Construction Projects

5- No.1 Easy Guide about VRF & VRV Systems

6- Your No.1 Simple Guide about Medical Gases in Projects

7- SMDB & FDB procedure of practical installation on site

8- Your No.1 Simple Guide about Medical Gases in Projects

9- The MEP Infrastructure networks in Construction Projects as you need to know