Organizations increasingly turn to Building Management Systems (BMS) to streamline their facility management processes as building technology advances.

A BMS is a centralized computer system that monitors and controls all the mechanical and electrical systems in a building.

It allows facility managers to gain greater visibility into the operation of the building’s various systems, leading to greater energy efficiency, cost savings, and increased occupant comfort.

One crucial component of the BMS is the field devices. These sensors, actuators, and controllers interface with the various building systems and provide data to the BMS.

Field devices are responsible for measuring temperature, humidity, lighting levels, and other critical parameters that affect the building’s performance.

They also act as the BMS’s eyes and ears, gathering data about the building’s performance and sending it back to the centralized control system.

This blog post will provide an overview of some of the different types of field devices commonly used in a BMS.

01- Differential Pressure Switch or DPS

A Differential pressure switch, differential pressure switch, or air differential pressure switch, commonly called DPS, it’s an advanced device that triggers an electric switch based on the differential pressure detected between two points.

If you would like to read more about this device, you can check this blog post.

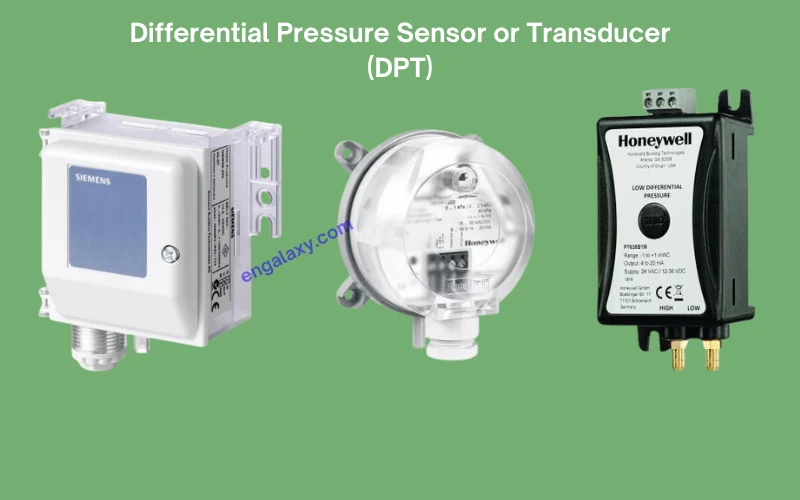

02- Differential Pressure Sensor or Transducer

It’s a motor that we install on the rotary damper, like the dampers of the HVAC ducts. We can see these dampers on the fresh air, return air duct, exhaust air duct, and supply air duct. So the primary function of this actuator is to control the opening and closing of the damper, either partially or fully.

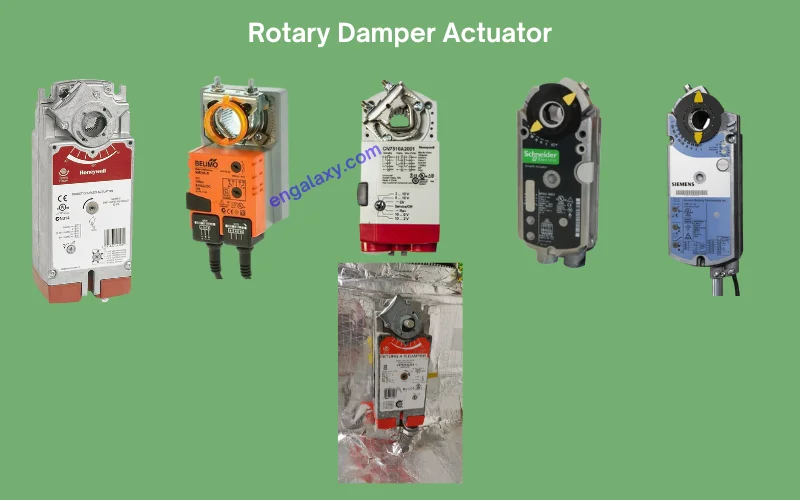

03- Rotary Damper Actuator

It’s a motor that we install on the rotary damper, like the dampers of the HVAC ducts. We can see these dampers on the fresh air, return air duct, exhaust air duct, and supply air duct. So the primary function of this actuator is to control the opening and closing of the damper, either partially or fully.

04- Linear Valve Actuator

We will use this actuator with the linear valves to control the fluid flow in a pipe.

An example is the actuator installed on two- or three-way linear valves in the chilled/hot water system.

05- Flow Switch

We can understand from its name that it will give a feedback signal with the status, either yes or no. We will use it to tell us whether there’s a flow of water or not.

06- Water Pressure Transducer

From its name, we can conclude two things. One, we will use it with the water system. Two, we will use it to measure the pressure of the water.

07- Water Pressure Switch

As it’s a switch, it will give a feedback signal, either yes, or no. Plus, we will use it with the water system.

08- Duct Smoke Detector

From its name, we can understand that we will use it with the HVAC ducts, and its function is to sense the existence of smoke inside the duct and send an alarm signal to the operator.

09- Temperature Sensor

We will use this field device to sense and measure the temperature in a space, like the outdoor air temperature.

10- Relative Humidity/Temperature Sensor

It’s a field device that will measure the relative humidity and temperature of the air.

11- Level Transducer

We will use it to measure the level of fluid inside its container, like a water tank, fuel tank, and so on.

12- CO sensor

We will use it to measure the concentration of carbon monoxide in the air. Otherwise, it will be toxic air that can cause the death of human beings. An excellent example of using this field device is the car parking areas, as we need to ensure the level of carbon monoxide in the air doesn’t exceed a certain level.

So, when this sensor measures the level of carbon monoxide and finds it’s a high value, it will send a signal to the BMS system. Based on that, the BMS system will send a signal to a control panel that will operate the fans in the basement, like Jet fans, which will help remove this polluted air outside the car parking area. So the level of carbon monoxide will be reduced.

By the way, the above devices are not all in the BMS system, but other field devices can be used with the BMS system.

Expert Advice

Whenever you’re ready to learn about the BMS system, this includes cables, VAV, AHU, Protocols, and many awesome things. There is a way that I can help you:

1- Enroll now in our Bestseller BMS Online course and watch+ 48 lectures; more new lectures will be added.

All our blog posts can be found on this link: