Water valves are imperative in a water system because they make it possible to turn the water on or off.

This means that water valves have a direct impact on the amount of water that is used.

As you can imagine, water valves are an essential part of a residential water system and a commercial system.

In residential settings, water valves are used to supply water to individual homes. Most of the time, this means that a water valve will be installed on the end of the pipe that leads directly to the home.

In commercial settings, water valves are often installed in the middle of the pipe, leading to the building’s water supply. This makes it easier for workers to turn off the water to that section of the building without having any issues.

What are the several functions of water valves?

– Controlling the flow of water in a system or process.

– Regulating and directing water flow.

– Providing safety for piping liquids, solids, gasses, or any fluid being used within a system.

Water valves are essential to providing safe access to running water with minimal risk of contamination from sources such as runoff due to rainwater.

They also maintain pressure when there is less demand on the supply line, which can help prevent bursting pipes that could lead to flooding inside homes caused by leaking gas lines and more!

As a public service, valves are an important component for supplying drinking water to the general public.

Methods of Opening Water Valves

Some valves are operated by turning a handle (or knob) on the valve.

Other valves require flipping, rotating, or pushing to open and close them.

Valves can be opened manually with tools such as pliers, wrenches, screwdrivers, hammers, and more.

Some of these are designed for this purpose exclusively! Others may need some modification before they work properly in this capacity.

– Manual opening/closing: Turning a handle (or knob), Flipping it side to side, or Rotating it so that the water flows through one way at a time – Push down on plunger when needed using the push-type valve.

– Tools used: Pliers, Wrenchs Screw

What are the categories of Water valves? Or What are the differences between a multi-turn valve and a quarter-turn valve?

One of the most common questions we get from our customers is the difference between a multi-turn valve and a quarter-turn valve.

The main difference is that you can adjust it incrementally with a multi-turn by turning it clockwise or counterclockwise.

With quarter-turn valves, they only have one position to control water flow, so if you want to open it more than halfway, you will need two valves.

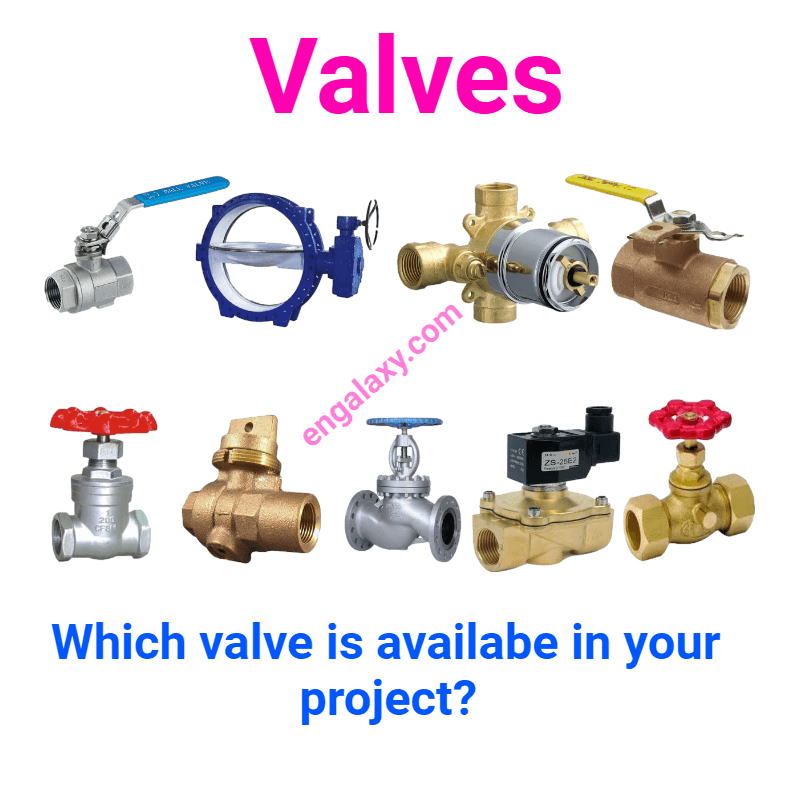

The most common types of Plumbing Water Valves in Projects

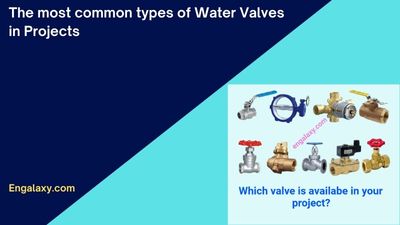

1- Ball Valve

Ball valves are used to regulate and control the flow of liquids. They are available in a variety of sizes and are made from various materials, including brass, steel, and plastic.

A ball valve is a type of quarter-turn valve that contains a ‘ball’ within the valve, hence the name.

It is held in place by force required to turn the handle and prevent the valve from fully rotating.

In this way, it blocks or unblocks the flow of fluid through the valve.

You can turn a ball valve by hand by simply grabbing the handle and turning it.

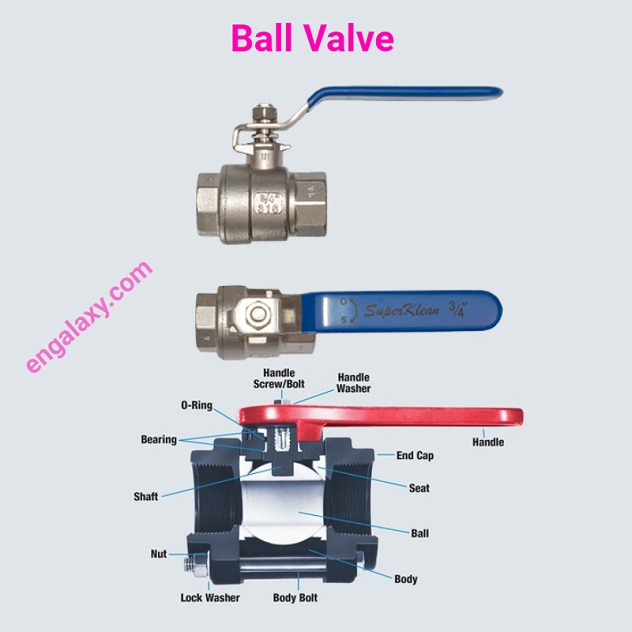

2- Gate Valve

A gate valve is a type of valve used to control the flow of a fluid through a pipe.

It is characterized by a vertical disk-shaped body through which the fluid travels. There is a hole through the center of this disc, through which a gate is placed.

The valve gate seals the valve stem and is lifted and lowered by a lever attached to a rod that passes through the disk. In this way, a gate valve is similar to a ball valve, which uses a ball as the gate.

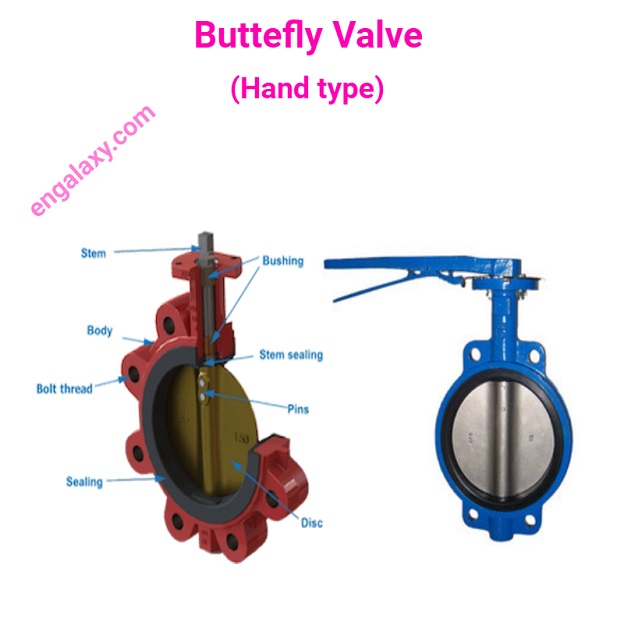

3- Butterfly Valve

A butterfly Valve is a Valve that opens and closes with a rotating disc rather than moving parts.

It is not a new type of Valve, but its use is growing rapidly in many industries. A butterfly valve is a type of quarter-turn Valve.

It may be a ball Valve, globe Valve, or gate Valve, in which a disc is mounted so that it may rotate around a central (vertical, horizontal, or diagonal) axis. With a quarter-turn rotation, the disc opens or closes the valve.

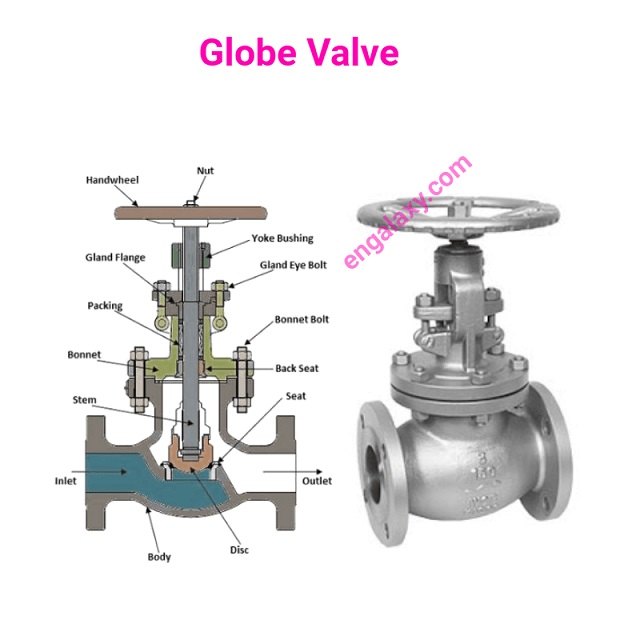

4- Globe Valve

A globe valve is a type of flow control valve which uses a spherical-shaped disk, known as a globe, mounted on a vertical axis.

There are also disk valves, which are the most common valves used to control water flow in plumbing pipes. The difference between a globe valve and a disk valve is that a globe valve uses an open disk, while a disk valve uses a closed disk.

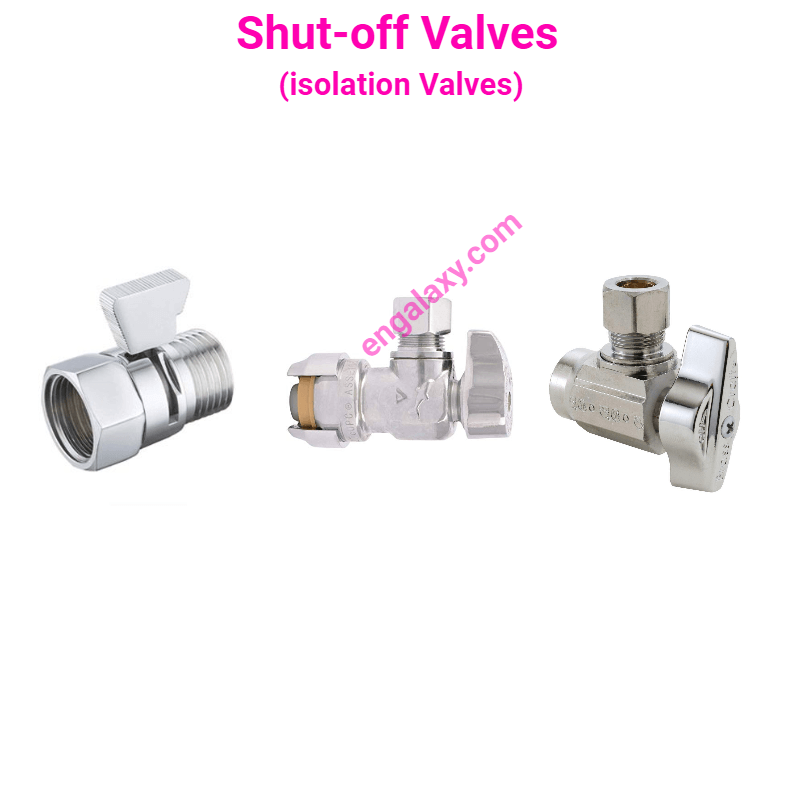

5- Shutoff Valve (Stop Valve)

The shutoff valve is a device that allows you to isolate a section of your plumbing from the rest of the system, so you can make repairs or undertake the process of removing and replacing pipes.

A shutoff valve is attached to a pipe, usually threaded on and tightened with a wrench.

Shutoff valves usually have a handle that may be turned with a wrench or with a turn of the hand, and some are automatic, closing when there is no pressure from the flowing water.

Shutoff valves can be adjusted to regulate the flow rate, and they are used in the plumbing of both residential and commercial buildings.

As a result, the shutoff valve is one of the most important components of any plumbing system and is also one of the most frequently used plumbing tools.

6- Pressure Reducing Valves

The pressure-reducing valve is a type of control valve that reduces water and gas pressure in the pipeline.

It can be used for a variety of purposes, including reducing the pressure of water in a sprinkler system (we are calling it a PRV valve), controlling the pressure of a gas appliance, or as a pressure-relief device.

Because of its simple design and versatile functions, the pressure-reducing valve is widely used in various sectors, such as water, gas, and oil.

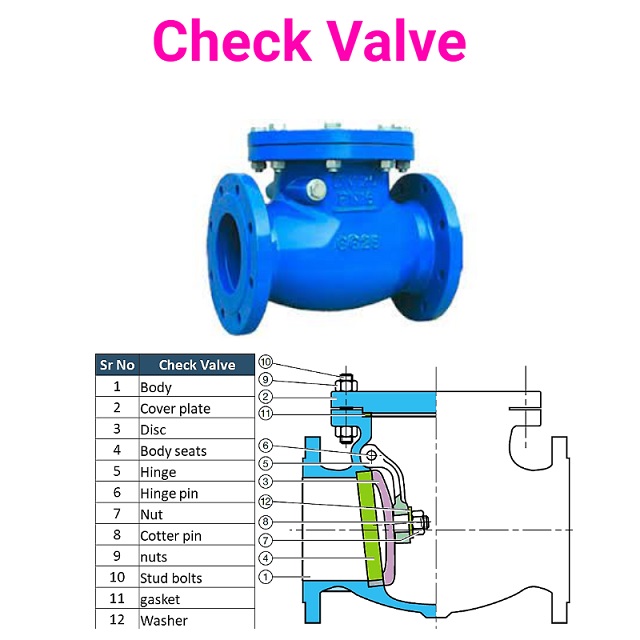

7- Check Valves

Check Valves are simple mechanical devices that prevent fluid from flowing in the opposite direction of its intended path.

Their basic operation is fairly simple: when fluid enters the check valve’s inlet, it opens a gate that allows fluid to pass into the check valve’s chamber.

When the pressure in the chamber is greater than the pressure in the inlet, the check valves close the gate, preventing fluid from passing back toward the inlet.

In the end, the water Valves are used in our everyday life, whether it comes to the hot water or the cold water, be it in the kitchen, bathroom, laundry room, garage, workshop or any other place where we can find it.

These valves should be selected according to different situations which may arise.

All our posts can be found on this link: