Did you hear before about the Solder Free Tube Connections?

Do you know where we use them and how to do them?

Do you know what is the difference between them and Soldering & Brazing?

Are you interested in the Mechanical or MEP installations on-site?

If your answer is yes to one or all the above questions, so this article is for you.

In this article, we will talk about the different common connection types that we use to connect the copper pipes together with their fitting.

Why do we use the copper pipes in the water and HVAC piping systems?

Copper is a valuable material because it has some really useful properties. It is heat resistant, corrosion-resistant, and cheap.

Because of these properties, copper is used in a variety of HVAC (heating, ventilation, and air conditioning) plus in water supply applications.

In the world of HVAC, a copper pipe is a special type of tubing used for transporting coolant, and it is used in all types of HVAC systems.

Metal piping is a pretty standard component of HVAC systems, but it does have a few drawbacks.

First, it is very expensive and difficult to replace parts. Additionally, if it is damaged, it can cause serious damage to the entire HVAC system, and if we need to maintain we used to weld it to overcome its damage, but it is very difficult to fit a replacement pipe in the same place.

That’s why the engineers found a new technique/method for connecting and repairing the metallic tubes and especially the copper tubes to avoid all the disadvantages of soldering the tubes. This is a new technique we call Solder Free Tube Connections.

Old Techniques of Joining the copper tubes and fittings

I will talk first about the most common techniques that we used for many years to join and connect the copper tubes and their fittings, these two techniques are Brazing and soldering.

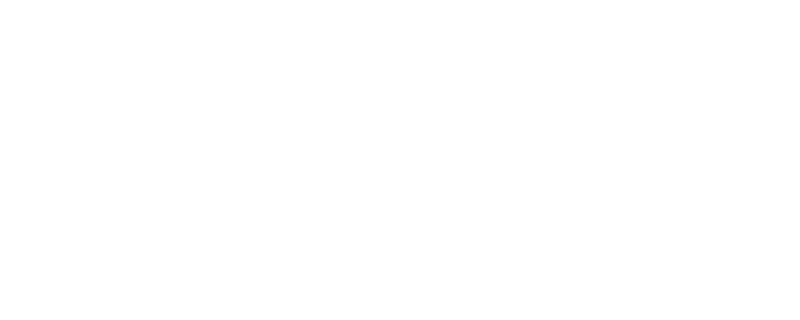

What is the difference between the Brazing and soldering of copper tubes?

Soldering and brazing are both processes that are used to join metals. While both processes are similar, but they are not identical.

In both brazing and soldering, the metals to be joined are first heated to a temperature at which they will flow freely, which allows them to be joined.

In brazing, the joining is achieved by sliding the two metals together, and in soldering, the joining is achieved by melting the metals and flowing the molten metal into the joint.

In this video made by Tigtime, you can see the difference between both processes.

Solder Free Tube Connections

Disadvantages of the Brazing and soldering of copper tubes in the Water Supply & HVAC system:

Soldering can be performed on thin metals that require minimal heat, but it can be inaccurate depending on the temperature and the type of metal used.

Grinding down the metal and connecting the pieces by melting them together is a pretty standard method of joining metal.

This is because this method is a lot easier than soldering, making it ideal for the hundreds of uses for pipes in HVAC & Water Supply systems.

Unfortunately, this method can also cause problems. For one, the pieces can be weakened by the heat of the brazing process, making it more difficult for air to flow through them. That means they could fail sooner, which would cause your HVAC system or Water Supply System to fail.

Moreover, Brazing is more expensive than Soldering.

Note: In Some Projects, the specifications say to use copper pipes for the water supply system, not PPR, as usual in most of the projects.

Solder-Free Tube Connections:

What are they? How do they work?

If you’ve ever heard of them, you probably think that they are a recent invention poised to change how we connect things as we know it. However, you may not know that they date back to the early 1900s and that the idea was inspired by and described by Nikola Tesla.

Soldiering & Brazing of metallic tubes is often causing problems in the installation and repair of refrigeration and air conditioning systems.

That’s why the engineers found a solution to overcome the problems caused by the soldering process. This new technique of connections we call it solder-free connection, and the normal soldering connections is finally a thing of the past.

What is the concept of making a solider-free connection?

This Solder-Free Tube Connection is created Completely without any heat generation, which means you save all the necessary safety precautions for soldiering.

The fire regulations and soldering permits cease to apply. So there’s no additional bureaucracy and bothersome waiting.

Elaborate safety gear and heavy soldiering equipment are no longer needed on construction sites, even in busy offices.

One of the most benefits of solder-free tube connections is that you can carry out installations without interrupting operations.

However, specialized companies in this type of connection, ” solder-free tube connections ” (Ex: VULKAN), don’t just make the installation is easier, but quicker to each knock reconnection is 40 percent faster than a shoulder joint.

Cause when Solder, even experienced professionals, can’t always avoid damaging the air conditioning system with heat or solder residue.

Handling lokring, on the other hand, is easy to learn and uncomplicated, so after only a short time, you’re able to apply a system quickly and reliably.

Step by Step How to make the Solder-Free Tube Connection practically On-Site:

1- First, deburr the tube and thoroughly clean the tube ends.

2- Use the stabilization insert to give the connection more stability.

3- Mark the insertion depth of the tube

4- Apply lock prep evenly to the entire cube circumference.

5- Lock prep penetrates even the finest cavities and fills them completely.

6- Now push the tube’s end all the way into the connector, and press the lokring into the connector using the hand assembly tool.

That’s all, as you can see, it’s straightforward.

No matter what connection you’re creating, lokring offers the best solution that fits every instillations situation.

For over 30 years, lokring tube connectors have been successfully applied in the refrigeration and air conditioning industry. More than one billion lock rings have been installed since then.

This is a summary of the tools & fittings that are used in the video during the Solder-Free Tube Connections :

1- TUBE DEBURRER

2- ABRASIVE MAT

3- STABILISATION INSERTS

4- PERMANENT MARKER

5- LOKPREP

6- JOINT

7- LOKRINGS

8- HAND ASSEMBLY TOOL WITH ASSEMBLY JAWS MB EVP.

All our posts can be found on this link: