Hi again. Today we will know step by step how to perform Busway Testing & Commissioning on-Site from A to Z.

1- Introduction

1.1- System Description:

A bus duct (also called a Busway) is a sheet metal duct containing either copper or aluminum busbars to conduct a substantial current of electricity. It is an alternative means of conducting electricity to power cables or cable-bus.

1.2- Scope:

The scope of work is to conduct Testing and commissioning for Busway Risers to confirm readiness to be placed safely in service, ensuring the project performance requirement and preserving a log of the testing measurements taken during commissioning for future reference.

1.3- Objective:

The purpose of this method statement is to define the step-by-step procedure to implement the correct practices for the Testing & commissioning of Busway Risers through the guidelines contained here to ensure that the job execution complies with the project specifications and serves the intended function to a satisfactory level.

2- Prerequisites to Procedure

2.1- Site Accessibility and Safety:

- Free access is provided to officially appointed personnel only

- A safe environment is provided in electrical rooms

2.2- Documentation for inspection:

- A method statement is approved, including test forms.

2.3- Quality Control Test reports and submittals:

- WIR for installation is cleared from the major items.

- WIR for testing all the cables connected to the BUSWAY RISER is approved.

2.4- Power on the requirement

- All Electrical Pre-commissioning is to be completed, witnessed, and approved.

3- Design Parameters

- Relevant manufacturer recommendations

- Relevant design and document approvals.

- Relevant materials approvals.

4- Reference Documents/Drawings

4.1- Specification Reference:

- Specification of project 16910

4.2- Relevant Codes / Standards:

- NFPA 70

- NEMA

- SASO

- UL

4.3- Approved Drawing Reference:

- Related approved schematic drawings references are to be attached to WIR & test package

4.4- Approved Schematic Drawing Reference:

- Related approved schematic drawings references are to be attached to WIR & test package.

4.5- Relevant Approved Material Submittal:

- Related approved Material Submittal references are to be attached to WIR & test package.

5- Pre-Start Checks/Pre-commissioning

List all pre-commissioning checks:

The following Checks shall be done for Busway Risers:

A- Ensure that the Busway Riser installation is complete and all electrical & mechanical comments on the installations are completed & approved.

B- Ensure that no damage has occurred between mechanical completion & pre-commissioning.

C- Check that the installation location is free of any water or construction debris.

D- Ensure that the BUSWAY RISER is tagged correctly & identified location-wise and service-wise as specified.

E- Ensure that the wiring termination to the Busway Riser is complete, tight & secure.

F- Ensure that the outgoing cables from the BUSWAY RISER are terminated in the respective equipment panels & adequately tagged and identified.

G- Ensure that the earthing of the Busway Riser is completed.

I- Ensure that the cables to the BUSWAY RISER are correctly tagged & identified.

6- Commissioning/Test Procedures

6.1- Insulation Resistance Test:

· Ensure Isolation of all incoming and outgoing cables.

· Apply a voltage of 500 volts DC between phase ‘R’ to Earth for 1 minute with phases Y, B & N shorted & earthed & record the values.

· Repeat the test for other phases as well.

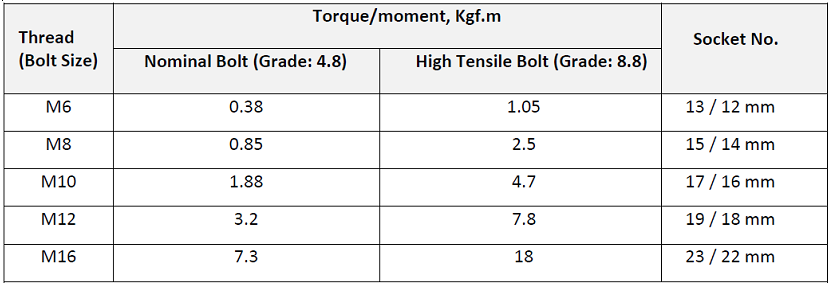

6.2- Busbar Torque Test

· Refer to the table below for the Torque Wrench setting with respect to the hardware size.

· Ensure the proper tightness of the busbar joints with the torque wrench.

· After confirming the correct tightness, apply a red mark on the hardware for indication.

6.3- Commissioning Procedure:

· You need to ensure that all the pre-commissioning checks are carried out successfully.

· The incoming supply of the Busway Riser shall be measured for current, voltage, frequency & phase sequence.

· Check trip operation of circuit breakers (where applicable).

· Check the incomer trip setting.

· Check the circuit breakers on/off function.

· Check the overload relay setting.

· Check timer setting.

7- Interface Procedure

· Permanent power should be provided.

8- Documentation

List all relevant test sheets.

· T&C- BUSWAY RISER Pre-Commissioning Check Sheet.

· T&C- BUSWAY RISER Commissioning Check Sheet.

· Instrument Log.

9- Demonstration Procedures

- After completing the procedures mentioned in section 6.0. The Inspection request with all relevant documents to be sent to Main Contractor for review and inspection.

- After initial verification by the Commissioning Manager, the PMCM will be invited to witness the works.

- After attaining approval, test/report sheets to be signed off from all mentioned in the signature block.

- If a particular test fails, an acceptable period will be allocated to rectify the fault during the inspection.

- Test/report sheets to be distributed as per Project Specifications.

10- Instrumentation

10.1- Personal Protective Equipment:

- Helmet.

- Gloves.

- Goggles.

- Safety Shoes.

- Hi-Vis. Vest.

10.2- Testing Equipment:

10.2.1- Digital Multimeter test tool used to measure two or more electrical values.

10.2.2- Phase Sequence / Rotation Tester

It’s used for detecting the sequence of the supply in three-phase electric circuits.

10.2.3- Clamp Tester

The tool used to measure very high currents

10.2.4- Torque Wrench

A tool that tights the connection bolts to a specific N.m setting

Notes:

· All instruments, testers, and tools will be calibrated and have a calibration certificate not older than 12 months on the test date.

· A Copy of the certificate will be submitted before the test, and it will be available at the site with the device.

11- Staffing

11.1- Testing & Commissioning Engineer

Facilitates all Testing and commissioning of MEP installations of the project, Testing, and commissioning, start-ups, and documentation

11.2- Senior Electrical/Mechanical Engineer:

Controls all the electrical/mechanical installation management processes.

11.3- Safety Engineer:

Responsible for ensuring the safety of the workers and the workplace during Testing and commissioning.

11.4- Commissioning Manager

Verify and approve the testing and commissioning of electrical/mechanical installations and documents before requesting inspections from PMCM/ Client representative.

11.5- PMCMs / Client Representative:

Verify the entire Testing and commissioning of electrical/mechanical installations to witness and approve the test on-site.

11.6- QC Engineer:

Coordinates with the site Engineers and Client Representatives with regards to Testing and commissioning and Hand-over process

Responsible for witnessing the test and will ensure all installation and Testing are approved based on specifications and standards

Should attend during Inspection, Testing & Commissioning, and handover.

11.7- Site Foreman/ Electrician:

To assist with the Testing and commissioning of electrical/mechanical works.

11.8- Supplier’s Representative:

To assess the Testing and commissioning of their owned/supplied electromechanical equipment.

12- Safety Aspects & Permit to Work Requirements

12.1- Health and Safety

12.2- Introduction

. All sub-contractors will comply entirely with JLL approved HSE plan / Ref.

. The contractor must adhere to the JLL health Safety& Environment Policy.

12.3- Safety Aspects & Permit to Work Requirements

· All employees involved in the activity shall undergo a site HSE induction course before the work site.

· Site activities shall be carried out safely according to the approved “Project Health, Safety and Environment Plan.”

· Commissioning team must follow the Client permit-to-work system (Internal) and Client LOTO procedures.

· The commissioning team must read, understand, and follow the JLL / Client LOTO procedures.

· Designated permit issuer/receiver or coordinator shall be appointed to control the commissioning area and commissioning works.

12.4 Training

All commissioning & testing personnel will attend a Safety Commissioning Meeting and pre-commissioning safety training before work commences.

12.5- Hazards Related to Testing & Commissioning

· The following HSE training shall be delivered to the person but not limited to:

- Working at height

- Hazards from electricity

- Use of Power/hand Tools

- Night working.

12.6- Risk Assessment and Control

· HSE Hazards involved in the activity have been assessed through the Hazards & Effects Management Process (HEMP) for every activity, and the outcome is recorded. The contents of the HEMP Register shall be disseminated within the shift supervisor/foreman’s teams through toolbox talks.

· Any new hazards identified other than in the HEMP regarding site conditions shall be assessed, and the Site Engineer/Supervisor shall take control measures before the commencement of any activity.

· The following control measures generally apply to all hazards that shall be adopted as a proactive measure, in addition, the specific controls identified in the HEMP register:

- Correct use & Maintenance of tools and equipment.

- Deployment of a competent personnel for the task.

- Conduct daily toolbox talks before work commencement.

- Good Housekeeping.

- Adequate and effective supervision.

- Provisioning appropriate PPEs based on the nature of the works.

- Awareness about emergency response.

12.7- First Aid / Medical Facility / Emergency Response

· Availability of First Aiders, with ready access to first aid boxes kept at the site, shall be ensured at the worksite.

13- Attachments

- Test Sheets

- T&C- Pre-Commissioning Check Sheet.

- T&C- Commissioning Check Sheet.

- Risk Assessment.

All our method statements are available on this link:

https://engalaxy.com/method-statements