FCU hookup, otherwise known as fan coil unit hookup, is an essential aspect of HVAC systems in commercial and residential buildings.

It involves the connection of a fan coil unit to the building’s water supply, which allows for the circulation of hot or cold water to maintain a comfortable ambient temperature. Valves play a crucial role in the FCU hookup process, controlling the flow and temperature of the water as it circulates through the unit.

These valves come in various types and sizes and are selected based on the specific requirements of the building and its HVAC system.

Our blog post will delve into the different types of valves used in FCU hookup and how it affects the overall performance of the HVAC system.

Firstly, let us know what the FCU is.

FCU is equipment of the chilled water system that is installed to provide cooling/heating for a specific space in the building.

It can be installed exposed or above the false as per the approval by the architect.

Usually, we have three pipes that will be connected to FCU if it includes only a water cooling coil; in this case, the first pipe is the chilled water supply line, which will be a steel pipe; the second pipe is the chilled water return line which will also be a steel pipe, and the third pipe will be the condensate drain line, and usually, it’s a plastic pipe.

But when the FCU includes two water coils, one for heating and one for cooling, in this case, we will have five pipes, two of them will be steel pipes to be connected to the cooling coil as supply & return, then we have other two steel pipes will be connected to the heating coil, and the last fifth pipe will be a plastic pipe to work as a condensate drain which will be in between the drain pane in the FCU and the drainage line.

Also, FCU includes a fan that sucks the air, either complete fresh air or return air from space; then it sends this air to a copper cooling or heating coil, in which the chilled/hot water flows through it, then the temperature of the water inside the FCU’s coil is responsible for changing the supply air temperature which will be forced to the space.

FCU Hookup and its connections:

Now, we will give a summary of the different valves and items that shall be available to provide proper function and also for proper maintenance to the FCU.

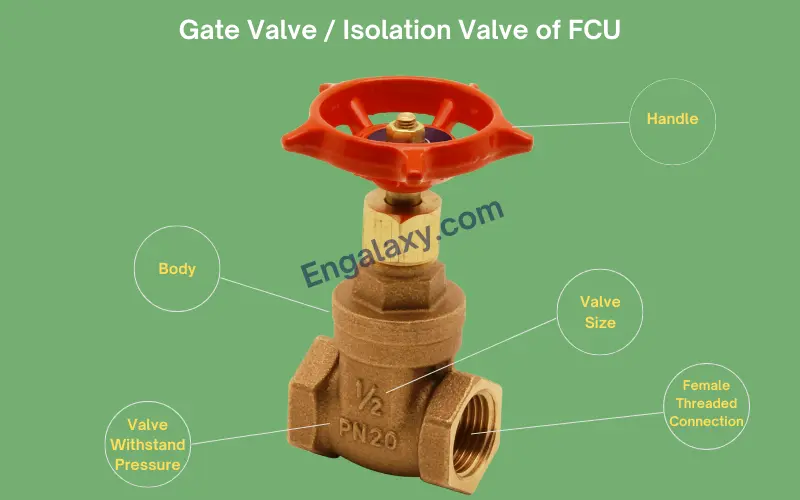

1- Gate Valve or Isolation Valve:

From its name, we can expect its function; we use it to isolate the different items connected with FCU for maintenance purposes or testing & commissioning FCU.

2- Flexible connection:

We use it to absorb the vibration caused by the FCU’s motor and avoid transferring this vibration to the fixed item like the pipe, and we install it directly after the coil of the FCU.

3- Bypass Valve:

We use it to create a bypass connection between the supply and return water pipes, and this connection is very important for flushing purposes to avoid the dirt and debris transferred from the pipes to the inner side of the coil that can damage it.

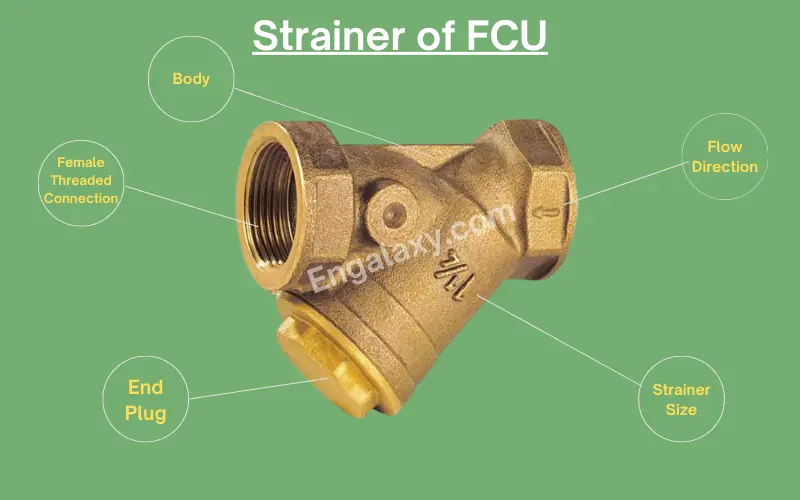

4- Strainer:

We will install it on the supply water line to the FCU to ensure no dirt will go to the inner side of the coil. We have an end plug at the end of the strainer, which we can remove for cleaning purposes.

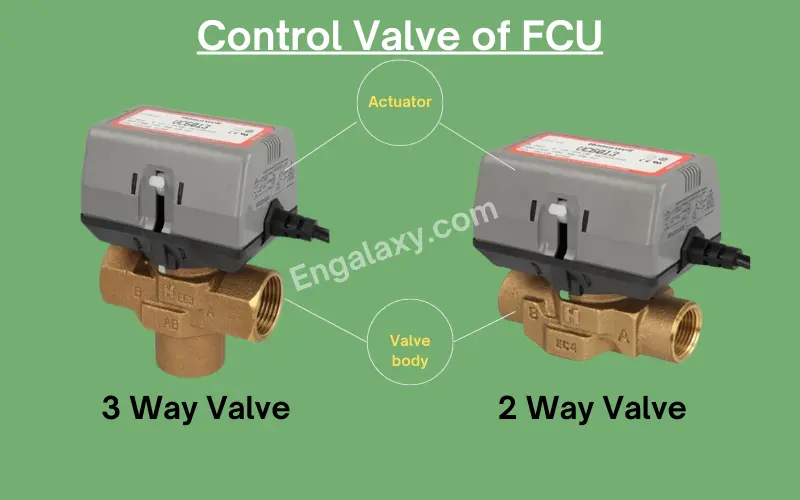

5- Control Valve complete with its actuator:

This valve will be installed on the return line of the cooling/heating coil when it’s a 2-way type, or we can use a 3-way valve on the bypass.

The purpose of this valve is to close or open and control the water flow inside the coil to change the temperature based on the temperature signal from the space until it reaches the set point value.

The control of this valve will be through an actuator that is attached to it.

The actuator will receive its signal from a BMS or the thermostat; then, it takes action either to open or close the valve.

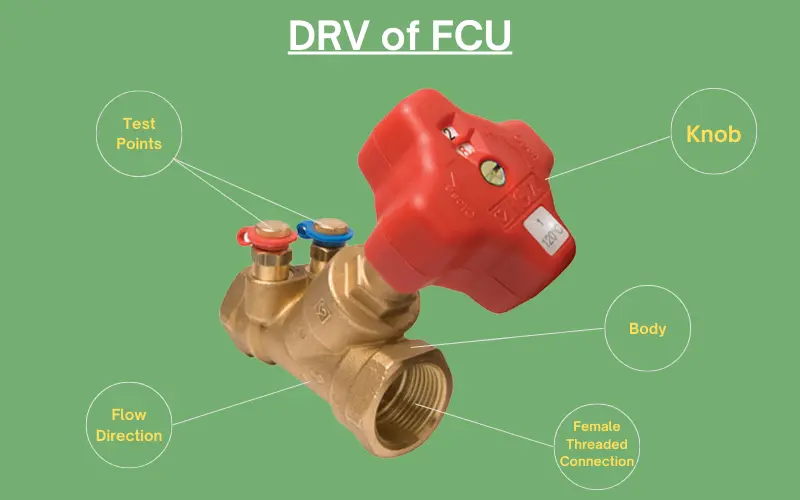

6- Balancing valve:

Also, it’s called a double regulating valve or DRV. It will be installed on the return water line, and it will be responsible for adjusting the flow rate of water inside the coil of the FCU and ensuring no overflow will go to the FCU.

The water balancing process happens once in the project cycle before the system’s operation.

By the way, we can replace the balancing+control valve with only one valve, which is PICV, which will be explained in another blog post.

All our blog posts can be found on this link: